Product Design • Product Development • Turnkey Manufacturing

• Customer Focused Partnerships; Value-Creating Engineering with Integrity.

• Exceptional Custom Product Design, Driven by Customer & Market Requirements.

• Custom Engineering of Consumer & Industrial Products.

• Start-to-Finish Product Development, Prototyping & Commercial Production.

• Turnkey Supply of Custom-Manufactured Products & Assemblies.

• Sourcing of Hard-to-Find Parts & Components, Domestic or Global.

• Servicing Customers from Inventors/Entrepreneurs to Large Companies.

Custom Product Design

Clearview Design & Manufacturing principals Tom Goth and Phil Blank have a combined more than 60 years experience in manufacturing process selection, optimization of materials, expert CAD design, prototyping technologies, production tooling, and bringing a wide variety of products successfully into commercial production and within budget. We have a passion for designing breakthrough products and exceeding customer expectations. We invest time and effort to help create our customer’s success in return for a long-term supply partnership.

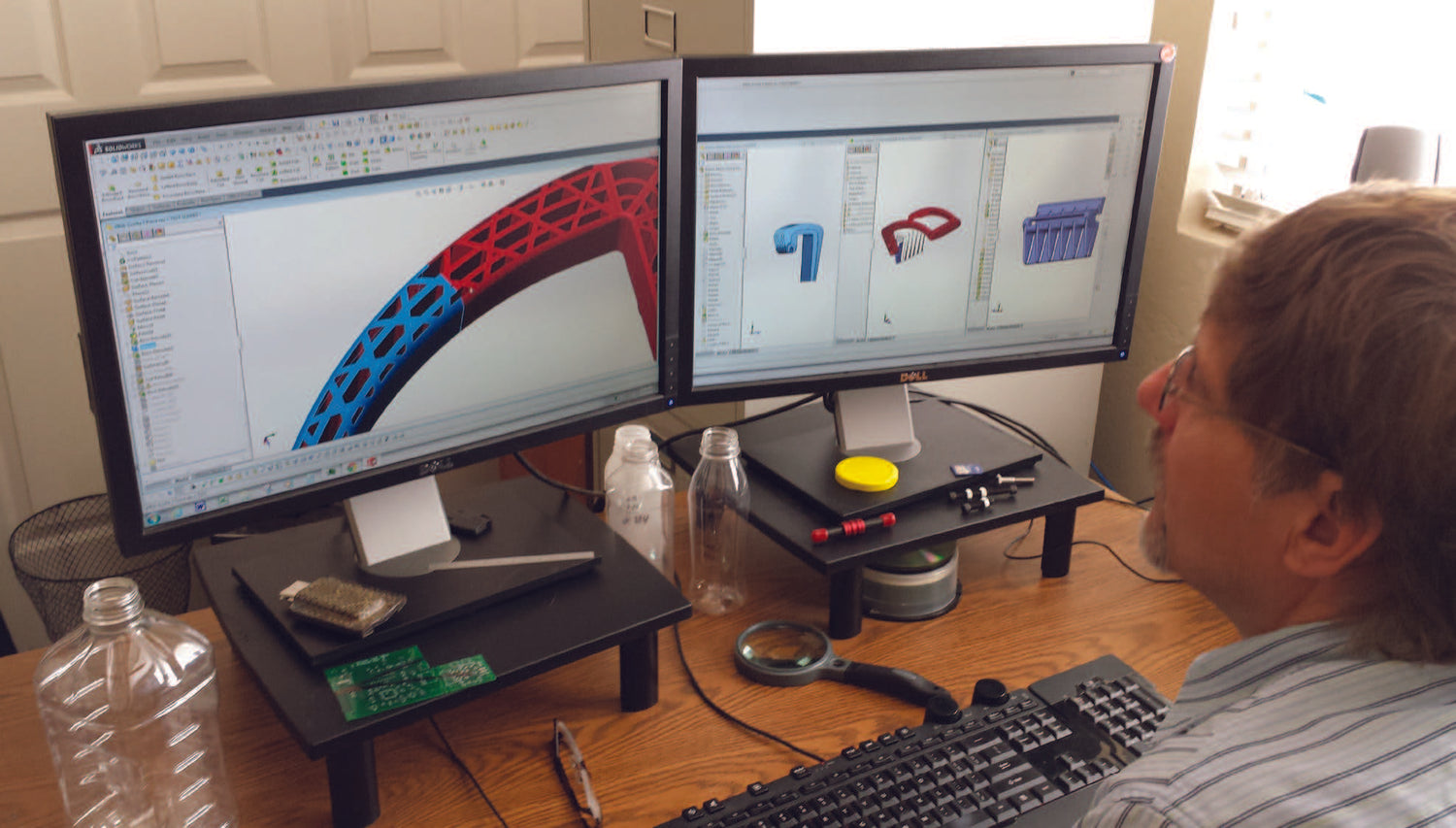

Engineering & CAD Services

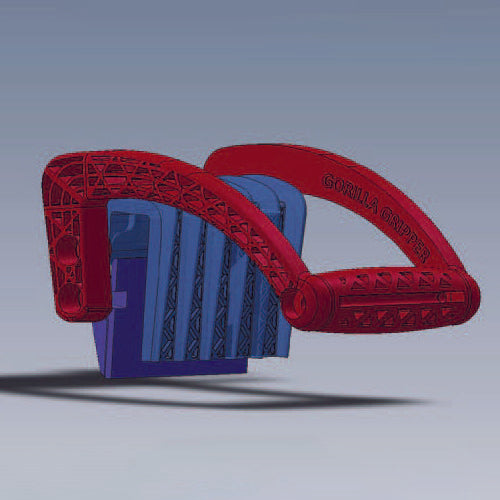

Clearview Design & Mfg creates the solid-model CAD DNA of great products for our customers. CAD solid models of customer products and assemblies are the blueprint for producing prototypes for evaluation and for commercial manufacturing production.

We use SolidWorks CAD software to design your parts from scratch, or to import existing CAD files created elsewhere for analysis, completion, or for prototyping/manufacturing. Existing products can be reverse-engineered using a variety of processes including laser scanning, CMM point cloud generation, and other techniques. Through our network of partners and associates, we are able to o er FEA (finite element analysis), CFD (computational fluid dynamics), and other advanced systems analysis.

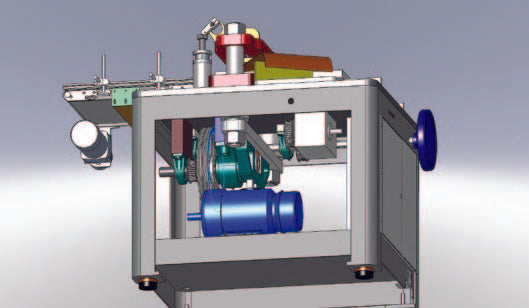

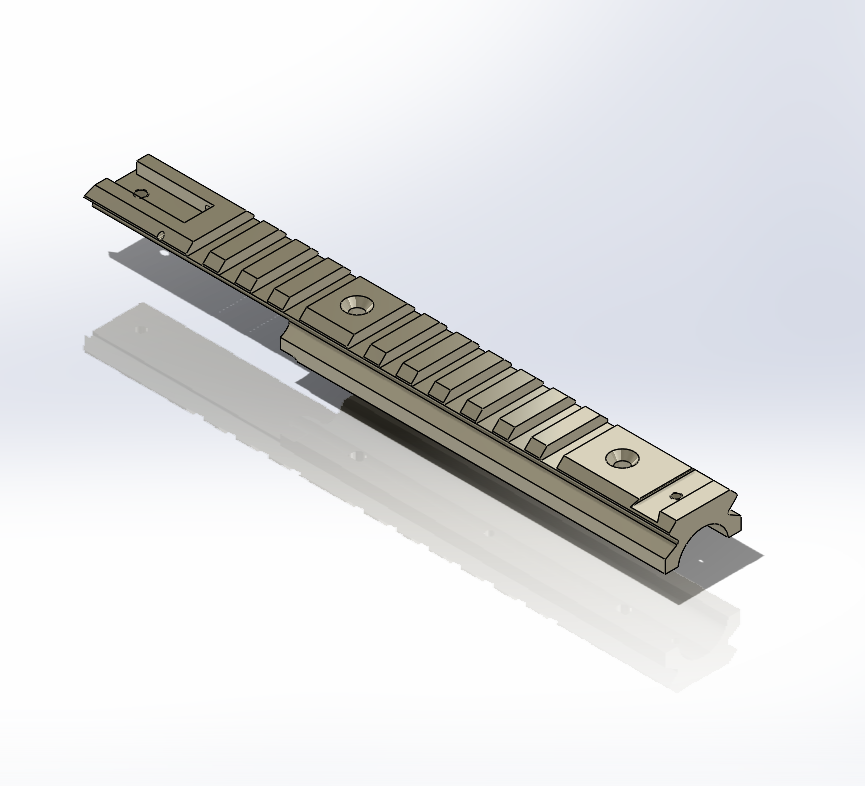

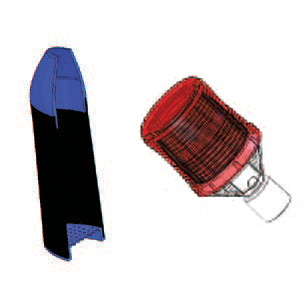

Computer Modeling, Rapid Prototyping and Unit Tooling

Our in-house SolidWorks CAD software is extremely useful for calculating product material volumes, surface areas, and many other physical attributes. It is also used to create assemblies, mechanical motion, and photo-like renderings. The engineering CAD files can be used to create physical models for evaluation via a wide variety of processes, including SLA, FDM, SLS, cast urethane and machining.

Turnkey Supply of Production Tooling & Custom-Manufactured Products

Partner with Clearview Design & Manufacturing to manage the development of required production tooling, the total supply chain, and supply your ongoing needs for your products and assemblies. We can lower your costs and allow you to focus on sales, marketing, and distribution efforts.

Processes Currently Employed for Plastic Parts & Assemblies

• Injection Molding • Extrusion Blow Molding • Thermoforming • Urethane Casting • Reaction Injection Molding • Compression Molding • Injection Blow Molding • Profile Extrusion • Die Cutting & Machining

Processes Currently Employed for Metal Parts and Assemblies

• CNC Vertical Milling • Swiss Machine • CNC Punch Press • Laser Cutting • Tube Bending • Powder Metal Sintering • Stamping • Welding, Heat Treating & Plating • Wire EDM • Fabrication & Assembly • CNC Horizontal Milling & Lathe • CNC Press Brake • Water Jet • Tube Swaging • Metal Injection Molding

Assistance with Market Research, Web-Site Design, Funding Resources, TV Commercials and More

Having been involved with the complete cycle of taking new products to market, we are able to help you with a wide variety of startup or launch requirements, either in-house or through referrals to our network of associates.

Call us or send an e-mail to see how we can help you move your business forward!